- Success Story: PT. SMART TBK. - Enhancing Equipment Reliability and Precision with EQUILIGN2

- Success Story: PT SSC Works Indonesia - Precision and Efficiency with FAG HEATER100-SMART

- Success Story: PT Sinar Karya Duta Abadi (Arwana Group) - Minimizing Downtime with FAG HEATER100-SMA

- Success Story: PT Merak Jaya Beton - Smarter Lubrication with Schaeffler Concept1

- Industrial News - Why Proper Mounting Of Bearings Is Crucial for Your Plant Operations

- Success Story: PT Perkebunan Nusantara VI - Proactive Condition Monitoring with Schaeffler OPTIME

- Success Story: PT Maju Mulia Plastik - Reliable Automatic Lubrication with CONCEPT1

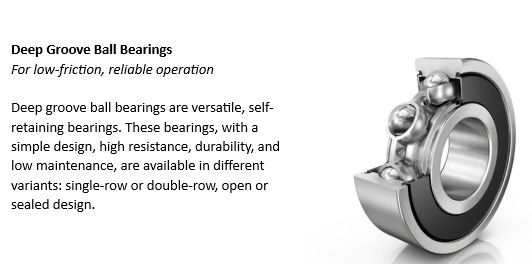

- Industrial News - Powering industrial performance

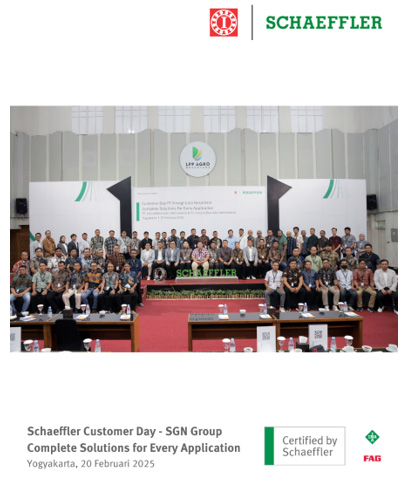

- Success Story PT Sinergi Gula Nusantara (PT SGN) Customer Day Yogyakarta 2025

- Industrial News - Maximizing efficiency

- Success Story PT. Century Bearindo International from PT Djabesmen

- Success Story PT. Central Bearindo International from PT Multi Spunindo Jaya Tbk.

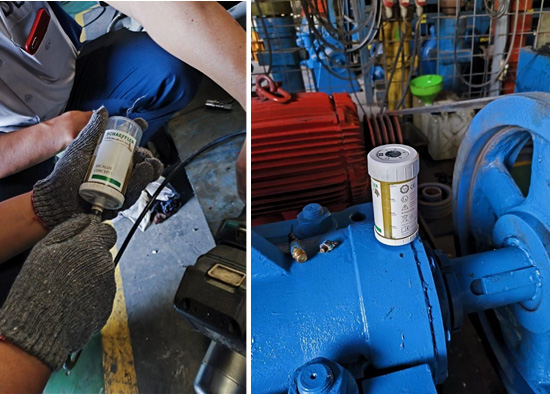

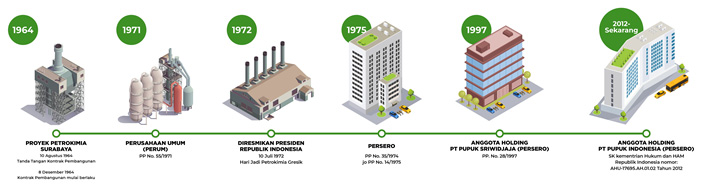

- Success Story PT. Central Bearindo International from PT. Petro Kimia Gresik

- Success Story PT. Central Bearindo International from PT. Pabrik Kertas Tjiwi Kimia Tbk.

- Success Story PT. Central Bearindo International from PT. Amerta Indah Otsuka

- Success Story PT. Central Bearindo International from PT. Perkebunan Lembah Bhakti 1

- Success Story PT. Central Bearindo International (Palembang) from PT. Bukit Asam Tbk.

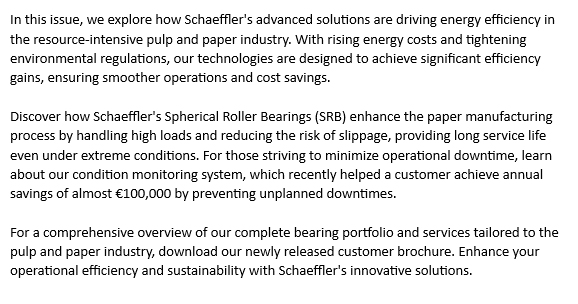

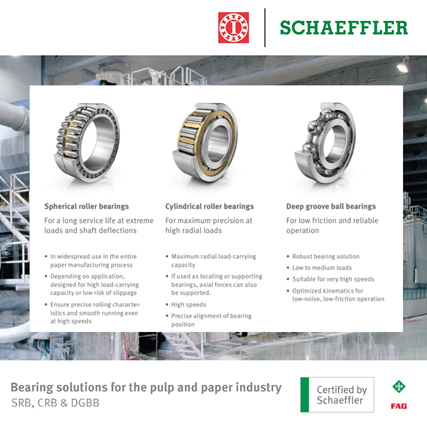

- BEARING SOLUTION FOR PULP & PAPER INDUSTRY

- SMART INDUCTING HEATING DEVICE

- LASER-EQUILIGN2 - 2

- LASER-EQUILIGN2

- The Smart Solution for Efficient Bearing Mounting! (MFT)

- IB Group Award

- Success Story CBI Jakarta from PT. Sorini Agro Asia Corporindo Tbk

- Success Story CBI Jakarta from PT. PINDO DELI PULP & PAPER

- Success Story PT. Century Bearindo International (CBI Surabaya) from PT. Indowire Prima Industrindo

- Success Story PT. Central Bearindo International (Medan) from PT. Solusi Bangun Andalas

- Success Story PT. Central Bearindo International (Pekanbaru) from KPN Corporation

- Success Story PT. Central Bearindo International from PT. ALP Petro Industry

- Success Story PT. Central Bearindo International (Pekanbaru) from KPN Corporation

- Schaeffler Industrial Symposium, Palembang-Indonesia

- Schaeffler Industrial Symposium, Medan-Indonesia

- Schaeffler Solutions: Customizing for Every Application

- You have got the goals, We have your solutions

- Schaeffler Lifetime Solutions - Keep Your Machines Rolling

- CBI Jakarta Success Story from PT. BUKAKA TEKNIK UTAMA

- English Indonesia Rule No. 24 likely to embolden other nations to grab more from mining

- PT. CBI New Depo in CIKARANG

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

If you have more detailed questions or inquiries, please get in touch with our customer service by clicking the link below to be directed to our branch office contacts.

https://centralbearindo.contactin.bio

If you have more detailed questions or inquiries, please get in touch with our customer service by clicking the link below to be directed to our branch office contacts.

https://centralbearindo.contactin.bio

If you have more detailed questions or inquiries, please get in touch with our customer service by clicking the link below to be directed to our branch office contacts.

https://centralbearindo.contactin.bio

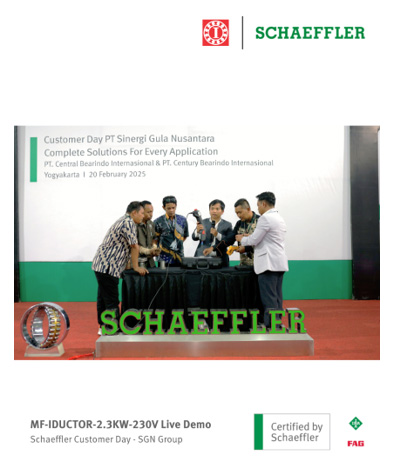

PT Sinergi Gula Nusantara (PT SGN) Customer Day Yogyakarta 2025

Thank you to everyone who attended and contributed to the SGN Customer Day held in Yogyakarta on February 20, 2025. The event was filled with engaging discussions, cutting-edge innovations, and vibrant networking opportunities.

One of the highlights was the live demonstration of the IDUCTOR 2.3KW 230V, showcasing its efficiency, speed, and safety in bearing installation using advanced induction heating technology. The demo received great enthusiasm from the participants, reflecting a strong interest in smart industrial solutions.

Another exciting feature of the event was the Live Product & Tool Display, where attendees could see, touch, and test various products and technologies firsthand. It was an excellent opportunity to explore practical solutions and gain valuable insights tailored to industrial needs. We truly appreciate the energy and participation from all attendees and look forward to seeing you at our next event!

#SGNCustomerDay #Schaeffler #Centralbearindo #schaefflerdistributor #fagdistributor #bearingdistributor #ptcbi

https://centralbearindo.contactin.bio

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

Customer: PT. Djabesmen

PT Djabesmen, a leading manufacturer of fiber cement roofs in Indonesia since 1971, has been looking for ways to improve its maintenance processes. With decades of experience in the building materials industry, the company has rigorously tested and refined its processes in areas such as quality assurance, procurement, service, distribution, and collaboration with suppliers. This dedication has enabled Djabesmen to effectively cater to the growing demands of the market. Today, Djabesmen roofs are widely used across Indonesia in numerous projects and have also gained international recognition, being exported to various countries around the globe. Their commitment to excellence and innovation has solidified their reputation as a trusted leader in the industry.

Background:

At first, the customer expressed interest in trying automatic lubrication and shared their feedback with PT Century Bearindo International. In response, Century Bearindo provided a detailed presentation on the CONCEPT1 system, explaining its features and benefits. During the presentation, Century Bearindo also promised to offer hands-on support, ensuring a smooth introduction to the product and helping the customer with their initial use.

PT Century Bearindo International (CBI) provided a comprehensive service to the customer, starting with a detailed offer that included installation services. They also demonstrated how to properly fill grease into the cartridge and guided each customer on calculating the correct amount of grease needed for their machinery. Additionally, CBI ensured customers understood how to set the timing on the lubrication tool, ensuring efficient and accurate usage of the automatic lubricator.

Product Advantages and Customer Benefits:

- Flexible Options: Choose between pre-filled ARCANOL lubricant cartridges or refillable empty cartridges for customized grease filling.

- Sustainable Design: Refillable cartridges can be reused up to three times, promoting environmental responsibility.

- Cost-Effective Solution: Delivers excellent value for money within its equipment category.

- User-Friendly Operation: Easy transition to automatic lubrication without the need for special tools.

- ATEX Certification: Ensures safe lubrication in hazardous environments.

- Optimal Lubrication Performance: Guarantees efficient lubrication for enhanced equipment performance.

- Consistent Lubrication: Provides reliable and steady lubrication, minimizing maintenance issues.

- Grease Waste Reduction: Decreases unnecessary grease consumption, supporting sustainability initiatives.

- Safety Enhancement: Improves safety during maintenance and operation.

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

Success Story: PT Multi Spunindo Jaya's Automatic Lubrication Optimization

PT Multi Spunindo Jaya Tbk is a leading nonwoven manufacturer in Indonesia, recognized for its cutting-edge manufacturing facilities and commitment to high-quality, reliable production. Operating under a Total Quality Management System, the company prioritizes continuous innovation, collaboration, and process improvement. PT Multi Spunindo Jaya sought to streamline its operations by reducing the manual labor required for machine maintenance, particularly in lubrication tasks that were time-consuming and prone to errors. The company attended an industrial lifetime solution seminar, where it was introduced to smart lubrication solutions that promised to transform how they managed equipment lubrication.

Action:

Understanding PT Multi Spunindo Jaya's need to optimize their lubrication process, PT Century Bearindo International (CBI) stepped in to provide a cutting-edge solution: the OPTIME C1 Smart Lubricator from Schaeffler. CBI's approach involved:

- Immediate Engagement and Consultation: Following the seminar, CBI quickly followed up with the team at PT Multi Spunindo Jaya, discussing their specific lubrication challenges and demonstrating how the OPTIME C1 system could meet their needs.

- On-Site Product Presentation and Customization: CBI provided a detailed introduction to the OPTIME C1, explaining its smart technology and how it could eliminate the need for manual lubrication checks. The system's intuitive mobile app allowed users to monitor lubrication points remotely and receive notifications when lubricators needed refilling or maintenance.

- Simplified Installation and Integration: CBI ensured that the OPTIME C1 was seamlessly integrated into PT Multi Spunindo Jaya's operations. The lubricator is easy to install, refill, and use, reducing the time and resources previously required for manual lubrication.

- Smart, Data-Driven Maintenance: CBI emphasized the OPTIME C1's award-winning smart technology, which allowed PT Multi Spunindo Jaya to check lubrication status via a mobile app, eliminating manual inspections and ensuring optimal lubrication levels at all times.

Customer Benefits:

Implementing the OPTIME C1 Smart Lubricator system provided PT Multi Spunindo Jaya with several critical benefits:

- Increased Uptime and Productivity: By automating lubrication, the OPTIME C1 reduced downtime caused by premature bearing failures and incorrect lubrication, ensuring smoother operations and longer machine life. Maintenance managers now had more time to focus on critical tasks rather than routine lubrication.

- Reduced Risk and Improved Safety: The OPTIME C1 eliminated the need for maintenance personnel to manually access lubrication points in hazardous environments, significantly reducing workplace accidents and keeping employees safer.

- Remote Monitoring and Peace of Mind: The OPTIME C1 provided maintenance teams with remote, real-time insights into lubrication points via the mobile app. Alerts and notifications allowed them to stay ahead of any potential issues, reducing the risk of failures and providing full confidence that machines were operating optimally.

- Cost-Effective and Sustainable Solution: The OPTIME C1 is not only cost-efficient but also eco-friendly. Its refillable cartridges can be filled with Schaeffler's ARCANOL grease or the customer's own lubricants, reducing waste and environmental impact while maintaining lubrication efficiency.

- Flexible Application Across Various Equipment: PT Multi Spunindo Jaya benefited from the versatility of the OPTIME C1, which is ideal for various applications such as electric motors, pumps, ventilators, and conveyor belts. This adaptability meant that the system could be deployed across multiple areas in the facility, simplifying overall maintenance.

Smart Lubrication: Revolutionizing Maintenance Management

This collaboration between PT Petro Kimia Gresik and CBI (PT Century Bearindo International) has proven to be a success, equipping the fertilizer giant with a cutting-edge condition monitoring system that not only enhances productivity and machine longevity but also sets the foundation for future growth with cloud-based analytics.

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

Success Story: PT. Petro Kimia Gresik's Optimized Condition Monitoring

PT Petro Kimia Gresik, Indonesia's largest and most comprehensive fertilizer producer, plays a pivotal role in meeting the nation's agricultural demands. Established in 1964 and officially inaugurated in 1972, the company has grown to produce 8.9 million tons annually, consisting of both fertilizer and non-fertilizer products. As the company expanded, so did the need for efficient operations. The rotating department at Petro Kimia Gresik faced challenges in maintaining optimal equipment performance, leading them to search for an advanced condition monitoring system to minimize unplanned downtimes and ensure smooth operations. Despite previous attempts to implement vibration monitoring solutions, the team struggled to find a reliable and accurate system.

Action:

PT Century Bearindo International (CBI), in collaboration with Schaeffler's Surabaya team, stepped in to deliver a versatile and modular solution designed to meet PT Petro Kimia Gresik's precise operational needs. The implementation process involved several key steps:

- Thorough Consultation and Customization: CBI initiated discussions to understand the specific challenges faced by the rotating department, offering insights into how the ProLink multi-channel condition monitoring system could help. - On-Site Trial and Evaluation: A comprehensive trial was conducted to showcase how the system could monitor vibrations in critical equipment such as motors, gearboxes, fans, and pumps. - Advanced Data Collection and Review: By using ProLink's templates and incorporating machine geometry data (bearing types, fan blade numbers, etc.), CBI customized the system to Petro Kimia's needs, ensuring accurate and reliable condition monitoring. - Integrated Learning Mode: ProLink's learning mode enabled dynamic adjustments to alarm thresholds, allowing the system to self-optimize over time for enhanced monitoring precision. - Tender Process Guidance: CBI provided support throughout the tender process, ensuring smooth compliance with all requirements and successful project approval. - Collaborative Installation: CBI worked with other contractors on site to complete cabling and system integration without interrupting daily operations. - Cloud-Ready for Future Expansion: CBI set up the ProLink system with an integrated cloud interface, enabling PT Petro Kimia Gresik to leverage Schaeffler's ConditionAnalyzer in the future, providing remote access and enhanced data-driven insights.

Customer Benefits:

The implementation of the ProLink multi-channel condition monitoring system brought several significant benefits to PT Petro Kimia Gresik:

- Versatile and Modular Design: The system's versatility allowed it to seamlessly monitor a range of equipment (rolling bearings, motors, fans, gearboxes, and pumps), offering flexibility in configuration to meet varying operational needs.

- Cost-Effective and Budget-Friendly: With early detection of potential failures, Petro Kimia significantly reduced unplanned downtimes and avoided expensive repairs, leading to improved operational efficiency and budget savings.

- Optimized Learning Mode: The ProLink system's learning mode enabled automatic adjustments of alarm thresholds, optimizing condition monitoring to fit the specific working environment and machinery behavior.

- Cloud Integration for Future Growth: The system is equipped with a cloud interface that enables future use of Schaeffler's ConditionAnalyzer, offering potential for remote monitoring and further optimization through advanced data analytics.

- Time Savings and Efficient Operation: Templates within the system made configuration quicker and easier, while the ability to gather and analyze machine data in real-time significantly sped up decision-making processes.

- Expert Support and Guidance: CBI provided ongoing support throughout the implementation, ensuring smooth installation and helping the team at Petro Kimia Gresik quickly learn and integrate the system's advanced features.

This collaboration between PT Petro Kimia Gresik and CBI (PT Century Bearindo International) has proven to be a success, equipping the fertilizer giant with a cutting-edge condition monitoring system that not only enhances productivity and machine longevity but also sets the foundation for future growth with cloud-based analytics.

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

Customer: PT. Pabrik Kertas Tjiwi Kimia Tbk.

Enhancing Machine Reliability at Tjiwi Kimia with Schaeffler OPTIME

PT Pabrik Kertas Tjiwi Kimia Tbk, a subsidiary of APP Group, is a major player in the paper manufacturing industry, producing a wide range of paper products including writing and printing papers, stationery, and packaging materials. With a production capacity of over 12,000 tons per year, ensuring the smooth operation of their machinery is crucial to maintaining production levels. However, like many industrial operations, Tjiwi Kimia faced the challenge of unplanned machine breakdowns, which led to costly downtimes and interruptions in their manufacturing process. Given the scale and complexity of their operations, a more efficient and cost-effective solution for monitoring machine health was needed.

Action:

PT Century Bearindo International (CBI) partnered with Schaeffler to introduce the OPTIME Condition Monitoring System at Tjiwi Kimia. CBI began by conducting a comprehensive location survey to identify key machinery that required constant monitoring. Collaborating closely with the Tjiwi Kimia team, CBI facilitated the installation of Schaeffler OPTIME's wireless vibration sensors on rotating equipment, particularly motors susceptible to frequent breakdowns.

The installation process was fast and seamless, with CBI providing on-site support to ensure that the sensors were properly set up and integrated with the OPTIME Mobile App, which provides real-time diagnostics. Within just a few hours, the system was up and running, allowing Tjiwi Kimia to monitor their critical machines with minimal disruption to production.

CBI followed up by managing the procurement process, ensuring a smooth transition from the trial phase to full implementation. CBI's expert team also provided training to Tjiwi Kimia personnel, making sure both beginners and experienced users could easily navigate the system and benefit from the intuitive design of OPTIME.

Customer Benefits:

With the deployment of Schaeffler OPTIME, Tjiwi Kimia has seen remarkable improvements in operational efficiency and machine uptime. The key benefits of OPTIME include:

- Cost-efficient Monitoring: Tjiwi Kimia can now monitor hundreds of rotating machines at just a few cents per machine per day-up to 50% cheaper than traditional manual monitoring using handheld devices. This has significantly reduced maintenance costs while increasing the reliability of the machines.

- Quick Installation: The wireless vibration sensors were installed and operational within minutes. No prior expertise was needed, allowing the factory's staff to quickly adopt the system and begin monitoring in real-time.

- Expert Knowledge & Diagnostics: The OPTIME Mobile App offers 24/7 professional diagnostics powered by expert algorithms and machine learning, enabling the factory's maintenance team to make data-driven decisions. The app's expert insights help detect potential issues like imbalances or misalignments weeks in advance, preventing costly breakdowns.

- For All Users: Whether beginners or experienced professionals, Tjiwi Kimia's team found OPTIME's user-friendly interface easy to navigate. The system provides decisive information that helps teams across the board make informed, timely decisions about machine maintenance.

Thanks to the implementation of Schaeffler OPTIME, Tjiwi Kimia now enjoys proactive condition monitoring, reduced downtime, and improved machine reliability, leading to higher production efficiency. CBI's seamless installation and ongoing support have empowered Tjiwi Kimia to stay ahead of potential issues, reducing the risk of unplanned disruptions and ensuring smooth, uninterrupted operations. This collaboration between Tjiwi Kimia, Schaeffler, and CBI has optimized the company's operations, ensuring their machinery performs at its best while minimizing unexpected production disruptions.

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

Customer: PT. Amerta Indah Otsuka

Solves Sensor Lifetime Issues with Schaeffler OPTIME

Founded in 1997, PT Amerta Indah Otsuka (AIO) is a prominent Indonesian company that emerged from a joint venture between Otsuka Pharmaceutical Japan and PT Kapal Api. Initially known as PT Kapal Indah Otsuka, the company later adopted its current name in 1999. AIO's flagship product, Pocari Sweat, is widely recognized and trusted in the market.

Challenge:

AIO encountered a recurring issue with the vibration sensors on their rotating machinery, where the sensors had an average lifespan of just three months. This frequent battery depletion led to increased costs and downtime, impacting the company’s productivity. AIO sought a solution that could resolve this issue and provide a reliable and cost-effective monitoring system for their machines.

Solution:

To address this challenge, Century (CBI) proposed and implemented Schaeffler OPTIME, an innovative Condition Monitoring solution. Schaeffler OPTIME is specifically designed for rotating machinery and provides scalable, efficient monitoring with minimal user effort. The steps taken by CBI were as follows:

1. Consultation and Direct Engagement:

- CBI conducted direct meetings with AIO to fully understand the technical issues and operational requirements.

2. Trial Instalation:

- AIO agreed to trial the Optime5 sensor system. CBI installed 5 Optime5 sensors and 1 Optime gateway to test the performance of the solution.

3. Proposal & Negotiations:

- Based on the trial results, CBI presented a tailored service and price proposal to AIO, offering an efficient, scalable solution for monitoring their machinery.

- Follow-up meetings and negotiations were conducted to ensure the solution met AIO’s expectations.

4. Implementation:

- Once AIO approved the purchase order for 5 Optime5 sensors and 1 Optime gateway, CBI quickly proceeded with the installation.

5. Ongoing Monitoring and Support:

- CBI continues to monitor the system performance, ensuring optimal operation and addressing any concerns.

Benefits:

The implementation of Schaeffler OPTIME has resulted in several significant benefits for PT Amerta Indah Otsuka:

- Regular monitoring of all machinery

- Extended Battery Life: The initial issue of sensor batteries depleting every three months was completely resolved, leading to long-lasting performance and minimized maintenance.

- Cost Savings: By eliminating frequent battery replacements and downtime, AIO has reduced operational costs significantly.

- Easy Installation and Use: The sensors were quick to install, taking just a few minutes without requiring any prior technical knowledge. This simplicity allowed AIO to scale the solution easily across multiple machines.

- Affordable Monitoring: The solution provided cost-efficient monitoring, allowing AIO to oversee hundreds of rotating machines at a fraction of the cost of manual monitoring.

- Expert Diagnostics: Schaeffler OPTIME's digital service, powered by expert algorithms and machine learning, ensures 24/7 monitoring and professional diagnoses. This has enabled AIO to make informed decisions based on real-time data.

- Scalability and Flexibility: The system's user-friendly nature accommodates both beginners and advanced users, making it adaptable to AIO's evolving needs.

Conclusion:

By implementing Schaeffler OPTIME, PT Amerta Indah Otsuka has successfully overcome its sensor lifetime challenges. The solution has provided long-term operational efficiency, cost savings, and an easy-to-use monitoring system, helping AIO maintain the reliability of their machinery and improve overall productivity. This partnership with CBI has proven to be an essential step in AIO's journey toward more effective and sustainable operations.

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

Customer: PT. Perkebunan Lembah Bhakti 1

PT. Perkebunan Lembah Bhakti 1, a palm oil plantation and processing company, faced significant challenges with frequent blower machine failures. The factory lacked an offline monitoring tool to detect machine conditions and identify faults.

Technical Details:

- Bearing: 22222E1KC3

- Motor Power: 90 kW

- Motor RPM: 1500 U/min

- Fan RPM: 935 U/min

Challenge:

The customer faced several significant challenges, including identifying the root cause of vibrations in their machinery and providing quick, onsite responses to these issues. Ensuring efficient and economical repair times was crucial to minimizing downtime, while swiftly resolving root causes was necessary to maintain operational continuity. Additionally, there was a pressing need to prevent further component damage caused by high vibration levels, which could lead to more extensive and costly repairs.

Solution:

PT. Central Bearindo International offered the FAG Detector III KIT as a solution. The FAG Detector III is a user-friendly, portable vibration measurement device designed to reliably identify machine conditions and eliminate their causes. With preinstalled standard configurations compliant with ISO 10816, it offers a plug-and-play solution that provides authoritative information on machine conditions without the need for extensive training or system setup. This enables rapid inspection of machinery and assemblies, ensuring quick and effective maintenance responses. PT. Perkebunan Lembah Bhakti 1 agreed to purchase the FAG Detector III KIT.

Benefits:

- Regular monitoring of all machinery

- Prevention of sudden breakdowns

- Improved maintenance scheduling

- Lebih aman bagi user/pengguna

- Ability to prepare spare parts that are not readily in stock

The FAG Detector III offers several advantages, making it an excellent choice for condition monitoring. It requires no prior knowledge to operate, allowing even inexperienced users to effectively monitor vibration and temperature simultaneously. The system supports both static and dynamic balancing on-site, ensuring comprehensive maintenance capabilities. With RFID technology, measurement points can be rapidly and accurately detected, and a wide range of options for analysis and presentation are available. Its user-friendly design, coupled with an excellent price/performance ratio, makes it a valuable investment. Additionally, the system offers limitless possibilities for development, ensuring maximum investment protection.

Currently, PT. Perkebunan Lembah Bhakti 1 is utilizing the FAG Detector III KIT for scheduled monitoring, enabling them to detect and address machine issues promptly, without the need for specialized skills.

One of the users shared this testimonial with us:

“Using the FAG Detector III KIT has transformed our maintenance process. We can now monitor our machines regularly, preventing unexpected breakdowns and ensuring we are always prepared with the necessary parts.”

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

Customer: PT. Bukit Asam Tbk.

Challenge:

At the Engineering & Manufacturing Unit Workshop of PT. Bukit Asam Tbk in Tanjung Enim, we are responsible for providing equipment to support the repair of operational production equipment for coal mining. Specifically, the repair and fitting section focuses on repairing gearboxes by replacing shafts, gears, and bearings. Currently, the REM Workshop already has an induction heater from another brand; however, it is not suitable for large bearings (diameter above 500 mm), and it can no longer be used optimally due to extensive damage.

A bearing heater is crucial in the REM Workshop because it not only speeds up the work, saving time and effort during the process, but also reduces damage during installation. This ultimately helps reduce costs, as the bearing's lifespan becomes more optimal compared to manual or hammer installation.

Solution:

PT CBI & Schaeffler recommend the Schaeffler Heater 400 Smart. This model has the advantage of handling bearings with diameters up to 850 mm and a maximum bearing weight of up to 400 kg. It features a touchscreen display, and heating can be controlled for both the inner and outer bearings thanks to the Delta-T dual temperature measurement with two magnetic temperature probes. This ensures faster and more even heating of the bearings. Additionally, the heater includes a logging function to save data or export it to a USB, which can serve as documentation for the work performed.

Benefits:

The benefits for customers using the Schaeffler Heater 400 Smart are as follows:

- User-Friendly Touchscreen: The Heater 400 Smart is ideal for situations requiring greater control over the heating process. Its modern touchscreen with clear graphics makes it easy to use.

- Delta-T Dual Temperature Measurement: This feature, including two magnetic temperature probes, allows for precise control of heating on both the inner and outer bearings. This ensures that the heating process does not damage bearing elements, thereby optimizing bearing lifespan.

- Handling Large Bearings: The Schaeffler Heater 400 Smart addresses the challenge of installing bearings with diameters above 500 mm. It can handle bearings up to 850 mm in diameter and a maximum weight of 400 kg, making installation quick and easy.

- Logging Function: The Schaeffler Heater 400 Smart includes a logging function that can save data or export it to a USB, providing documentation of the work performed.

- Reduced Downtime and Costs: Using the Schaeffler Heater 400 Smart makes the installation of large bearings (diameters above 500 mm) faster and easier, reducing downtime and ultimately lowering costs compared to previous methods.

One of the users at PT. Bukit Asam Tbk provided feedback:

“We have seen a significant improvement in heating efficiency and speed, which directly impacts our workshop's productivity. We would like to thank you for recommending the Schaeffler Heater 400 Smart. The implementation of this heater has added great value to our workshop, and we look forward to continuing our collaboration with CBI/Schaeffler to further enhance our efficiency and service quality in the future.”

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

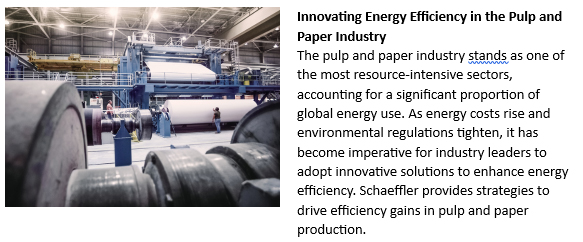

Schaeffler provides tailor-made bearing technology and services for the paper and pulp industry. Schaeffler has extensive expertise thanks to decades collaborating with well-known paper machine manufacturers and with maintenance and production departments.

In pulp preparation, spherical roller bearings and cylindrical roller bearings are commonly used. Spherical roller bearings are predominant in the paper-making process. For accessory units of paper-making machines such as motors, gears, fans, and pumps, deep groove ball bearings, angular contact ball bearings, and tapered roller bearings are typical. In the fields of finishing and converting, spherical roller bearings, angular contact ball bearings, and cylindrical roller bearings are standard. Additionally, FAG provides accessories and housings suitable for standard rolling bearings.

If you have more detailed questions or inquiries, please get in touch with our customer service by clicking the link below to be directed to our branch office contacts:

Link: https://centralbearindo.contactin.bio

#Schaeffler #Centralbearindo

#bearings #SRB #CRB #DGBB #sphericalrollerbearing #schaefflerdistributor #fagdistributor

#bearingdistributor #ptcbi #pulpandpaper

The inductive heating devices from Schaeffler are known for their quality, safety, and efficiency. The two BASIC and SMART series for workpieces weighing up to 1,600kg give customers from all sectors and industries an extensive portfolio, depending on demand and requirements.

All HEATERs ensure uniform, controlled heating and consistently high-quality installation. The fast and safe heating process is also gentle on the workpieces. For this purpose, they are always automatically demagnetized after being heated. Users can also lower their operating costs, thanks to the energy-efficient heating and short mounting times.

If you have more detailed questions or inquiries, please get in touch with our customer service by clicking the link below to be directed to our branch office contacts:

Link: https://centralbearindo.contactin.bio

#Schaeffler #Centralbearindo

#mounting #dismounting #MFT #bearings #schaeffler distributor #fagdistributor #bearingdistributor #ptcbi

#Puller #Dismounting #BearingDismounting

The precise alignment of rotating shafts is essential for cost-effective production in every industry. It reduces energy consumption, increases machine availability, and extends the machine’s lifecycles.

LASER-EQUILIGN2, the new generation of laser alignment systems for horizontal applications, features maximum precision, extreme efficiency, and convenient operation. Single-laser technology enables precise measurements in any situation. LASER-EQUILIGN2 can be quickly and easily installed. The handheld tablet simplifies operation by guiding users through the alignment process step by step.

If you have more detailed questions or inquiries, please get in touch with our customer service by clicking the link below to be directed to our branch office contacts:

Link: https://centralbearindo.contactin.bio

#Schaeffler #Centralbearindo

#mounting #dismounting #MFT #bearings #schaeffler distributor #fagdistributor #bearingdistributor #ptcbi

Another successful commissioning with Schaeffler LASER-EQUILIGN2! Proud to continue building trust with our customers through Schaeffler's lifetime solution tools. From INA to FAG bearings, we're committed to delivering excellence every step of the way.

The precise alignment of rotating shafts is essential for cost-effective production in every industry. It reduces energy consumption, increases machine availability, and extends the machine’s lifecycles. Schaeffler LASER-EQUILIGN2!, the new generation of laser alignment systems for horizontal applications, features maximum precision, extreme efficiency, and convenient operation. Single-laser technology enables precise measurements in any situation. Schaeffler LASER-EQUILIGN2! can be quickly and easily installed. The handheld tablet simplifies operation by guiding users through the alignment process step by step.

If you have more detailed questions or inquiries, please get in touch with our customer service by clicking the link below to be directed to our branch office contacts:

Link: https://centralbearindo.contactin.bio

#Schaeffler #Centralbearindo

#mounting #dismounting #MFT #bearings #schaeffler distributor #fagdistributor #bearingdistributor #ptcbi

Introducing Schaeffler Medium Frequency Technology (MFT): The Smart Solution for Efficient Bearing Mounting!

Our engineers are utilizing MFT technology to streamline the mounting process for bearings. Mounting and dismounting large bearings and workpieces efficiently is a significant maintenance challenge.

Schaeffler Medium Frequency Technology (MFT): a game-changer for such maintenance tasks. This solution not only simplifies the process but also reduces installation and removal time by half, ensuring workpiece protection and enhancing safety for all involved. With its user-friendly mobile heating device, MFT is revolutionizing the industry.

If you have more detailed questions or inquiries, please get in touch with our customer service by clicking the link below to be directed to our branch office contacts:

Link: https://centralbearindo.contactin.bio

#Schaeffler #Centralbearindo

#mounting #dismounting #MFT #bearings #schaeffler distributor #fagdistributor #bearingdistributor #ptcbi

Thrilled to announce that International Bearings was recognised for achieving the Schaeffler Top Sales Achievements 2023 Award in Southeast Asia and the Pacific region, at the Schaeffler Asia Pacific Industrial Partner Days 2024!

This award is a testament to the hard work and dedication of our entire team, who consistently strive to deliver the best solutions and services to our valued customers and partners. We extend our heartfelt gratitude to Schaeffler for this recognition, and we look forward to continuing our successful partnership and delivering outstanding results in the years to come.

Customer: PT. Sorini Agro Asia Corporindo Tbk

PT. Sorini Agro Asia Corporindo Tbk (SOBI) bergerak dalam bidang produksi industri (sorbitol, dekstrosa monohidrat, maltodekstrin, maltosa dan hidrogen), perdagangan dan jasa, sehubungan dengan itu, untuk menyediakan fasilitas untuk produksi, pengolahan dan fasilitas lainnya sehubungan dengan kegiatan serupa.

Challenge:

Sebagai salah produsen sorbitol yang cukup dikenal, banyak bearing digunakan dalam berbagai mesin produksi PT. SORINI. PT. SORINI sangat memprioritaskan kebutuhan mereka untuk sebuah alat pemanas bearings yang tidak hanya mampu bersaing dengan merek pesaing, tetapi juga harus tersedia segera untuk digunakan. Mereka juga menginginkan training yang komprehensif untuk memastikan penggunaan alat ini secara efisien.

Solution:

PT CBI memberikan rekomendasi untuk menggunakan SCHAEFFLER HEATER100. Saat proses pemasangan, bearing harus dipanaskan secara merata. Jika produksi panas terlalu tinggi, hal ini dapat menyebabkan perbedaan suhu antara bagian dalam dan luar bearing, yang pada hasilnya, dapat menyebabkan retak atau distorsi di bearing tersebut. Metode pemasangan bearing yang lembut dan aman, dicapai melalui pemanasan induksi yang memastikan bahwa bearing yang selalu disiapkan dan dipasang pada suhu ideal untuk pemasangan yang benar secara teknis.

Benefits:

Customer mendapatkan sebuah alat SCHAEFFLER HEATER100 dengan harga yang bersaing dan pengiriman yang cepat, serta mendapatkan jaminan layanan yang penuh dari CBI, dengan begitu secara langsung customer mendapatkan penghematan serta jaminan yang jelas dari CBI.

Schaeffler HEATER100 dirancang untuk memenuhi kebutuhan pelanggan dengan kemampuan memanaskan bearings yang memiliki diameter dalam minimum 70mm, diameter luar maksimum 500mm, dan berat maksimum hingga 100kg.

Benefits dari Schaeffler HEATER100:

- Pemanasan yang merata dan terkendali untuk kualitas pemasangan yang baik secara konsisten

- Pemanasan terjadi dengan cepat dan aman, sambil melindungi bearing dan mesin tsb.

- Pengurangan biaya operasional berkat pemanasan hemat energi dan waktu pemasangan yang singkat

- Perlindungan bagi orang dan mesin

Salah satu user di PT. SORINI memberi feedback: "Heater100 dari Schaeffler adalah alat luar biasa yang telah membantu kami menghemat banyak waktu dalam proses pemasangan bantalan. Selain itu, proses pemasangan menjadi lebih bersih dan tidak memerlukan penggunaan minyak atau pembakaran. Sangat memudahkan dan efisien!"

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

Customer: PT. PINDO DELI PULP & PAPER

PT. Pindo Deli Pulp and Paper Mills adalah salah satu Produsen Tissue dan Kertas Terbesar di Indonesia. PT. Pindo Delip Pulp and Paper Mills mengolah bahan baku yaitu pulp menjadi beberapa macam jenis kertas, meliputi kertas printing dan kertas nonprinting, yang didistribusikan di Indonesia bahkan sampai ke luar negeri. Perusahaan ini memiliki banyak Mesin Kertas dan Mesin Tissue yang beroperasi secara terus menerus dengan proses yang berkesinambungan.

Challenge:

Apabila terjadi kerusakan mendadak pada salah satu bearing, motor, atau gearbox di pabrik, hal ini dapat mengakibatkan berhentinya operasi seluruh mesin produksi. Berhentinya mesin produksi secara mendadak dapat berdampak signifikan pada kelangsungan operasional perusahaan, yang meliputi berkurangnya produktivitas, peningkatan downtime, dan potensial kerugian finansial.

Solution:

Solusi yang ditawarkan oleh PT CBI adalah pemasangan sensor wireless Schaeffler OPTIME di seluruh titik kritis pada mesin Kertas dan Mesin Tissue pelanggan kami. Hasilnya, pelanggan kami telah menyetujui langkah ini dengan memasang awal sebanyak 122 sensor di dua mesin Kertas mereka.

Benefits:

Penggunaan Schaeffler OPTIME membawa sejumlah manfaat yang langsung dapat dirasakan:

- Pemasangan yang mudah dan cepat

- Ringkas tanpa kabel:

- Monitoring Real-Time yang Lengkap: Hasil pengukuran dapat dipantau secara real-time di berbagai perangkat, termasuk monitor, laptop, dan smartphone.

- Kemudahan Penggunaan: Schaeffler OPTIME dapat digunakan dengan mudah oleh siapa pun karena hasil pemantauan disajikan dalam beragam bentuk, seperti indikator warna, teks penyebab potensial, serta data vibrasi dan suhu yang terukur.

- Mendisplay Raw Data: Timewave form dan FFT.

- Mencegah terjadinya Unplanned Shutdown

- Pemantauan Beragam Peralatan: Sensor ini dapat digunakan untuk memonitor berbagai peralatan, termasuk motor listrik, unit bearing, gearbox, pompa, kompresor, dan lainnya.

- Memiliki ingress protection class tertinggi IP69K, sehingga dapat di pasang di area Indoor dan Outdoor.

- Jaringan Mesh Network: Schaeffler OPTIME menggunakan jaringan "MESH NETWORK" yang menghemat jumlah gateway yang digunakan.

- Machine Learning: Sensor ini memiliki fungsi Machine Learning yang memungkinkan adaptasi terhadap karakteristik masing-masing mesin, sehingga tingkat pre-alarm dan alarm lebih akurat sesuai dengan kebutuhan.

PT. Pindo Deli Pulp and Paper Mills memiliki rencana untuk menambah lebih banyak sensor SCHAEFFLER OPTIME untuk dipasang di mesin kertas dan mesin tissue lainnya. Keputusan ini menunjukkan komitmen mereka untuk meningkatkan efisiensi dan kehandalan operasi mereka melalui pemantauan yang lebih luas dan mendalam menggunakan teknologi terkini. Dengan tambahan sensor OPTIME, mereka akan dapat mengoptimalkan pemeliharaan, mencegah kerusakan tak terduga, dan memastikan kelancaran produksi dalam jangka panjang.

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

Customer: PT. INDOWIRE PRIMA INDUSTRINDO

PT INDOWIRE PRIMA INDUSTRINDO adalah Perusahaan Produksi Kabel Otomotif, Corrugated Tube & Vinyl Tube di bawah Bantuan Teknis oleh Sumitomo Wiring System, Ltd. Japan.

Challenge:

Di pabrik PT INDOWIRE PRIMA INDUSTRINDO sering terjadinya downtime dikarenakan rolling bearing damage, unbalance dan misalignment. Kejadian downtime tidak terduga seperti ini menghambat proses produksi yang mengakibatkan banyak waktu yang terbuang dan proses produksi menjadi tidak efisien. Customer menginginkan sebuah alat pengukur vibrasi yang pintar dan mudah digunakan, untuk mendeteksi dan memonitor mesin mesin di pabrik.

Solution:

Solusi yang di tawarkan oleh PT CENTRAL BEARINDO INTERNATIONAL adalah menggunakan SCHAEFFLER SMART CHECK KIT. SmartCheck Kit dari Schaeffler adalah sistem pengukuran online modular yang ringkas, inovatif, untuk continuous monitoring terhadap parameter mesin dan proses secara terdesentralisasi.

Benefits:

Dengan penggunaan Schaeffler SmartCheck Kit, PT INDOWIRE PRIMA INDUSTRINDO telah memberikan beberapa manfaat:

- Kemudahan Penggunaan: SmartCheck Kit dirancang agar mudah digunakan, sehingga memudahkan user untuk mengoperasikan dan memanfaatkan sistem dengan efektif.

- Pencegahan Downtime: Dengan kemampuan untuk mendeteksi dan mengidentifikasi masalah terkait getaran secara cepat, user dapat mengambil tindakan yang diperlukan untuk mencegah downtime yang tidak terduga. Dengan menangani masalah sebelum mereka memburuk, perusahaan dapat meminimalkan gangguan produksi, mengoptimalkan efisiensi, dan mengurangi kerugian waktu produksi yang berharga.

- Solusi yang Efisien Biaya: SmartCheck Kit menawarkan solusi yang efisien biaya. Meskipun memiliki anggaran investasi yang kecil, kit ini memberikan dampak yang signifikan dengan menyediakan pemantauan terus menerus dan deteksi dini terhadap masalah mesin potensial. Hal ini membantu menghindari biaya perbaikan, penggantian, dan kerugian produksi yang terkait dengan downtime yang tidak terduga.

Secara keseluruhan dengan menggunakan SmartCheck Kit, PT INDOWIRE PRIMA INDUSTRINDO dapat menjaga operasi yang lebih lancar, meningkatkan produktivitas, dan memastikan masa pakai mesin yang lebih lama, sehingga meningkatkan efisiensi dan mengurangi biaya.

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

Customer: PT. SOLUSI BANGUN ANDALAS

PT. Solusi Bangun Andalas adalah perusahaan industri yang memproduksi semen dan berlokasi di Lhoknga, Banda Aceh. Semen Andalas adalah salah satu produk semen yang dihasilkan oleh PT. Solusi Bangun Andalas, anak perusahaan dari PT. Solusi Bangun Indonesia Tbk (SBI).

Challenge:

Pabrik PT. Solusi Bangun Andalas pernah mengalami kerusakan parah akibat bencana tsunami beberapa tahun lalu. Setelah bencana alam tersebut, perbaikan dan rekondisi dilakukan pada peralatan yang mengalami kerusakan. Beberapa unit dianggap masih dapat direkondisi dan diperbaiki, sementara unit yang mengalami kerusakan parah diganti.

Selama rekonstruksi dan perbaikan peralatan yang dianggap masih dapat digunakan beberapa waktu lalu, salah satu unit vital yaitu Vertical Raw Mill tetap dipertahankan untuk digunakan, meskipun unit tersebut pernah terkena dampak bencana tsunami. Berdasarkan kondisi tersebut, diperlukan peralatan yang dapat mengatasi kondisi berikut:

- Unit telah beroperasi selama lebih dari 20 tahun dan pernah mengalami bencana alam/tsunami.

- Unit tersebut belum pernah dilakukan Pembongkaran/Overhaul

- Unit termasuk Critical Equipment.

- Diperlukan peralatan pendukung Realibility Equipment

Solution:

PT CBI berupaya memberikan solusi penggunaan Schaeffler SmartCheck beserta kelengkapannya yang mampu memberikan akses kepada pihak Maintenance untuk:

- Memantau kondisi komponen internal di dalam gearbox dan electric motor penggerak Vertical Raw Mill secara REAL TIME.

- Menganalisis potensi kerusakan yang muncul pada komponen-komponen penggerak Vertical Raw Mill saat beroperasi dan dapat melakukan perkiraan/perencanaan perawatan saat shutdown.

- Memperoleh data atau referensi teknis secara akurat berdasarkan laporan hasil analisis data getaran dan suhu secara akurat, memungkinkan pemberian data TRENDING terkait kinerja yang diperoleh dari Schaeffler SmartCheck.

- Memberikan jaminan keandalan mesin yang lebih aktual dan mencegah potensi kendala produksi yang lebih akurat dengan memanfaatkan DATA/Informasi yang diperoleh dari Schaeffler SmartCheck.

- Memantau secara online, di area lokal, dan dapat diakses secara global secara remote.

Benefits:

Dengan pengaplikasian Schaeffler SmartCheck di mesin vertikal, pengguna memperoleh manfaat sebagai berikut:

- Memantau kondisi Mesin Vertical Raw Mill secara real-time sehingga dapat menganalisis kondisi dan kinerja mesin tanpa harus membongkar unit.

- Memantau secara online dalam kondisi real-time oleh pihak lain yang diberikan otoritas oleh tim Maintenance Lhoknga melalui jaringan Internet sehingga dapat dipantau oleh pihak lain di luar area di mana mesin beroperasi.

- Data yang diperoleh dari perangkat Schaeffler SmartCheck dapat digunakan untuk menganalisis kondisi bearing, sistem gigi, dan perangkat berputar lainnya yang terdapat dalam sistem gearbox tersebut.

- Peralatan ini juga dapat digunakan pada peralatan lain untuk menganalisis potensi kerusakan pada mesin yang dipasang peralatan SchaefflerSmartCheck tersebut nantinya.

Testimonial dari salah satu maintenance user di pabrik:

“Dengan menggunakan Schaeffler SmartCheck ini membantu untuk menganalisa tingkat vibrasi dan signal temperature mesin, ini membantu kami mencegah ada-nya down-time mesin di pabrik. Ini meningkat-kan produktivitas pabrik kami.. Penggunaan SmartCheck juga gampang digunakan untuk kami.. Terima kasih Schaeffler & PT CBI!”

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

Customer: KPN Corporation

KPN Corp adalah perusahaan induk yang didirikan pada tahun 2019 dan berpusat di Jakarta. Sebagai unit bisnis, KPN Corp mengawasi berbagai komoditas, termasuk perkebunan, semen, properti, perdagangan, pengiriman dan logistik, serta energi.

Di sektor perkebunan, bisnis utama kami adalah pemanenan dan pengolahan Tandan Buah Segar, Minyak Sawit Mentah, Kernel Sawit, Minyak Kernel Sawit Mentah, dan Cangkang Kernel Sawit. Kegiatan bisnis berlokasi di Riau, Jambi, Sumatera Selatan, Kalimantan Barat, Kalimantan Timur, Sulawesi Barat, dan Papua.

Sebagai salah satu Perusahaan Pabrik Sawit terbesar di Indonesia, KPN Corp memiliki pabrik pengolahan kelapa sawit yang sangat sibuk. Dimana kondisi ruangan dalam bangunan pabrik sangat krusial, karena bisa mempengaruhi proses produksi maupun sirkulasi bagi orang-orang yang bekerja di dalamnya. KPN Corp memakai banyak fan/blower untuk menjaga sirkulasi udara yang baik dalam ruangan, dan untuk menciptakan aliran udara kuat.

Challenge:

Proses pemasangan bearing masih menggunakan teknik traditional dan dengan cara yang tidak tepat seperti di-ketok dan di-masak dengan menggunakan minyak. Sehingga sering terjadi-nya bearing berbunyi, pengoperasian yang tidak teratur, indentasi di bearing (bekas gesekan), atau retak.

Solution:

Solusi yang di tawarkan oleh PT CENTRAL BEARINDO INTERNATIONAL adalah menggunakan heater HEATER20 BASIC. Metode pemasangan bearing yang lembut dan aman, dicapai melalui pemanasan induksi yang memastikan bahwa bearing yang selalu disiapkan dan dipasang pada suhu ideal untuk pemasangan yang benar secara teknis.

Benefits:

Manfaat yang langsung di rasakan oleh Kpn Corporation ini dalam penggunaan HEATER 20-BASIC adalah:

- Penggunaan yang Mudah / User-Friendly

- Proses pemanasan yang lebih merata

- Waktu pemanasan yang sangat cepat, terutama jika di bandingkan dengan metode Oil Bath

- Lebih aman bagi user/pengguna

- Membuat Usia Pakai Bearing dan Shaft lebih optimal

- Design yang ringkas dan kokoh

“Dengan menggunakan HEATER 20-BASIC, proses pemasangan bearing menjadi sangat cepat dan efisien karena tidak membutuhkan banyak orang untuk melakukannya. HEATER 20-BASIC juga compact, jadi mudah untuk dibawa ke mana-mana dan penggunaannya sangat mudah untuk kami para user.” Kata salah satu user di KPN Corp.

Saat ini unit Induction Heater dari SCHAEFFLER telah di gunakan sebanyak 7 unit di group Kpn Corporation.

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

Customer: PT. ALP PETRO INDUSTRY

PT ALP Petro Industry adalah salah satu pabrik oli yang paling modern yang ada di Indonesia dengan kapasitas produksi 40.000 MT per tahun dengan berbagai spesifikasi produk tertinggi. Pabrik dengan dua bagian utama yakni Refinery dan Blending pelumas oil yang terletak di Gempol, Pasuruan, Jawa timur.

Challenge:

Saat proses mounting, alignment yang tepat pada shaft sangat penting untuk mencapai efisiensi tinggi dan keandalan mesin berputar. Konsekuensi yang mungkin terjadi adalah unbalance or misalignment, dan dalam kasus terburuk, downtime yang tidak direncanakan.

PT. ALP Petro Industry menginginkan sebuah perangkat yang dapat digunakan untuk melakukan alignment shaft dengan baik. PT. CBI diharapkan untuk dapat memberikan rekomendasi alat yang sesuai dengan budget customer, termasuk memberikan pelatihan penggunaan dan aftersales services yang baik.

Solution:

Setelah melakukan pertemuan, survey dan diskusi dengan customer, Solusi yang di tawarkan oleh PT CENTURY BEARINDO INTERNATIONAL adalah alat SCHAEFFLER LASER EQUILIGN. PT CBI juga memberikan training mengenai penggunaan alat kepada pelanggan dengan praktek langsung di lapangan.

Benefits:

SCHAEFFLER LASER EQUILIGN adalah alat alignment system untuk shaft yang berada di motor, pompa, ventilators, dan gearbox dengan rolling bearings. Berkat desain yang kokoh dan fungsi yang berguna, SCHAEFFLER LASER EQUILIGN sangat cocok untuk digunakan dalam maintenance. Perangkat ini dapat membimbing pengguna langkah demi langkah melalui prosedur pengukuran hingga penentuan status alignment yang tepat. Teknologi laser-nya lebih disukai oleh customer, karena metode pengukuran ini lebih cepat dan lebih akurat.

Hingga 50 file pengukuran dapat disimpan langsung di perangkat ini. Bahkan jika operasi terputus, data akan diamankan secara otomatis, dan proses dapat dilanjutkan tanpa masalah. Yang paling penting adalah pekerjaan shaft alignment sudah dapat dilakukan oleh customer sendiri, menghasilkan hasil yang cepat, akurat, dan hemat biaya.

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

Customer: KPN Corporation

KPN Corp adalah perusahaan induk yang didirikan pada tahun 2019 dan berpusat di Jakarta. Sebagai unit bisnis, KPN Corp mengawasi berbagai komoditas, termasuk perkebunan, semen, properti, perdagangan, pengiriman dan logistik, serta energi.

Di sektor perkebunan, bisnis utama kami adalah pemanenan dan pengolahan Tandan Buah Segar, Minyak Sawit Mentah, Kernel Sawit, Minyak Kernel Sawit Mentah, dan Cangkang Kernel Sawit. Kegiatan bisnis berlokasi di Riau, Jambi, Sumatera Selatan, Kalimantan Barat, Kalimantan Timur, Sulawesi Barat, dan Papua.

Sebagai salah satu Perusahaan Pabrik Sawit terbesar di Indonesia, KPN Corp memiliki pabrik pengolahan kelapa sawit yang sangat sibuk. Dimana kondisi ruangan dalam bangunan pabrik sangat krusial, karena bisa mempengaruhi proses produksi maupun sirkulasi bagi orang-orang yang bekerja di dalamnya. KPN Corp memakai banyak fan/blower untuk menjaga sirkulasi udara yang baik dalam ruangan, dan untuk menciptakan aliran udara kuat.

Challenge:

Untuk saat ini, user di Pabrik KPN Corp masih menggunakan Vibration Pen untuk melakukan pengurukuran vibrasi pada motor dan fan. Dikarenakan tidak dapat melakukan pengukuran vibrasi dan alignment yang akurat hingga banyak muncul unbalance pada fan di pabrik.

Solution:

Solusi yang di tawarkan oleh PT CENTRAL BEARINDO INTERNATIONAL adalah menggunakan FAG DETECTORIII KIT + DETECTORIII BALANCING KIT dari Schaeffler untuk memudahkan customer melakukan pengecekan vibrasi fan lebih cepat dan akurat.

Benefits:

Manfaat yang langsung di rasakan oleh user di Kpn Corporation dalam penggunaan DETECTORIII KIT + DETECTORIII BALANCING KIT adalah:

- Dapat langsung di gunakan balancing on site tanpa harus melepas fan.

- Dapat langsung mendeteksi masalah dengan akurat, seperti masalah bearing, konstruksi, alignment, dan lain-lain.

- Dapat langsung menggukur atau ambil data beberapa fan sekaligus.

Dapat mengukur atau mengambil data pada fan dengan kecepatan minimal 500 rpm.

“Wah.. dampaknya terasa sangat signifikan bagi kami para pengguna di lapangan, proses pengukuran vibrasi pada fan menjadi lebih mudah dan jauh lebih akurat dibandingkan sebelumnya. Tingkat terjadinya unbalance/ketidakseimbangan sangat berkurang, karena pengukuran vibrasinya yang jauh lebih akurat.” Kata salah satu user di KPN Corp.

Saat ini unit DETECTORIII KIT + DETECTORIII BALANCING KIT dari SCHAEFFLER telah di gunakan sebanyak 3 set unit di group Kpn Corporation.

Jika Anda memiliki pertanyaan yang lebih detail atau ingin melakukan inquiry, silakan hubungi layanan pelanggan kami dengan mengklik link dibawah ini untuk diarahkan ke informasi kontak cabang-cabang kami.

https://centralbearindo.contactin.bio

Schaeffler Industrial Symposium

Saturday, 26 August 2023

Novotel Palembang South Sumatera, Indonesia

On 26 August 2023, we have all gathered for the Schaeffler Industrial Symposium held in Novotel Palembang. We are deeply grateful to all of you who attended and contributed to this fantastic event. Your presence made it a true celebration of knowledge sharing and collaboration. We had the opportunity to showcase the latest Schaeffler technologies, concepts, and products for Lifetime Solutions, and it wouldn't have been possible without your keen interest and engagement.

Thank You for Making #SchaefflerSymposium2023 a Success!

Schaeffler Industrial Symposium

26 July 2023

Hotel Grand City Hall

Medan, Indonesia

It was a great pleasure to welcome numerous guests to this year’s Schaeffler Industrial Symposium in Medan. Many thanks to all those present for taking the time to exchange ideas together and for their interest in our latest technologies, concepts, and products for lifetime solutions.

Stay Connected with Us

PT. CENTRAL BEARINDO INTERNATIONAL

Jl. Samanhudi No.21M, RT.1/RW.7, Ps. Baru,

Kecamatan Sawah Besar, Kota Jakarta Pusat,

Daerah Khusus Ibukota Jakarta 10710

https://centralbearindo.contactin.bio

Customer: PT. BUKAKA TEKNIK UTAMA

Sebagai salah satu Perusahaan dalam Pembuatan dan Penyediaan Peralatan Khusus terbesar di Indonesia, PT BUKAKA TEKNIK UTAMA memiliki fasilitas workshop yang sibuk.

Proses mounting/pemasangan bearing harus di lakukan dengan presisi dan dengan cara yang cepat dan tepat, agar usia pakai bearing dan komponen peralatan lain-nya dapat bertahan lama.

Challenge:

Banyak bearing yang di gunakan seperti deep groove ball bearing dan spherical roller bearing with cylindrical bore, yang selama ini di pasang dengan menggunakan metode pemanasan, namun sering di temukan staff maintenance / production masih menggunakan cara konvensional dan kurang tepat, seperti Blowtorch ataupun Oil Bath. PT BUKAKA TEKNIK UTAMA juga ada menggunakan Induction Heater merk lain, namun temperature-nya menurut operator kurang stabil dan sering kali bermasalah sehingga waktu yang di gunakan sangat lama.

Solution:

Solusi yang di tawarkan oleh PT CENTRAL BEARINDO INTERNATIONAL adalah menggunakan SCHAEFFLER Induction Heater. Di-tawarkan kedua seri, BASIC HEATER dan SMART HEATER.

Dan pada akhirnya PT BUKAKA TEKNIK UTAMA setuju untuk membeli HEATER100-BASIC.

Benefits:

Manfaat yang langsung di rasakan oleh PT BUKAKA TEKNIK UTAMA dalam penggunaan HEATER100-BASIC adalah:

- Penggunaan yang Mudah / User-Friendly

- Proses pemanasan yang lebih merata

- Waktu pemanasan yang sangat cepat, terutama jika di bandingkan dengan metode Oil Bath

- Lebih aman bagi user/pengguna

- Membuat Usia Pakai Bearing dan Shaft lebih optimal

- Dapat di gunakan untuk objek lain selain bearing, seperti V-Pulley

- Design yang ringkas dan kokoh

Saat ini unit Induction Heater dari SCHAEFFLER telah di gunakan sebanyak 2 unit di PT BUKAKA TEKNIK UTAMA, dan mereka juga berencana untuk menambah unit Induction Heater SCHAEFFLER seiring perkembangan unit usaha mereka.

Indonesia’s Rule No. 24 likely to embolden other nations to grab more from mining

Indonesia surprised the global mining community last week after a new rule - Government Regulation No. 24 of 2012 – was quietly announced on the mining ministry’s website.

The country – southeast Asia’s largest economy – will now require all foreign mining companies to sell majority stakes in their mining operations to locals by the tenth year of production.

Indonesia, with a population of 240 million, is the world’s premier thermal coal exporter, a tin powerhouse and is also rich in gold and copper.

Freeport McMoran’s Grasberg mine in the west Papua, a province of Indonesia, is one of the world’s biggest mines. It has the globe’s richest gold deposit and is second in copper.

Grasberg has been the site of violent clashes, sabotage and strikes over many years. Mining makes up roughly 12% of Indonesia economy and Grasberg is the country’s largest taxpayer.

Freeport and other miners operating in Indonesia are currently locked in royalty discussions with the government and some in the industry have speculated that the new regulation is not much more than a ploy to strengthen the government’s hand in negotiations.

An editorial in the Jakarta Post argues that Rule 24 should not have come as a surprise, but nevertheless takes the Indonesian government to task over its timing which “seems to make things even murkier and heightens uncertainty as, over the last few months, the government has been strong-arming foreign miners over contract re-negotiations [...] and [to] submit concrete business plans to build processing plants or smelters as they can no longer export unprocessed minerals after 2014.”

A growing list of nations – and not just radical fringe territories such as Zimbabwe or Venezuela – but stable jurisdictions including Poland, Ghana and Botswana are pushing for greater control and ownership of the resource sector on top of higher taxes and royalties.

South Africa recently stepped back from nationalization, but is nevertheless tightening its grip on the industry. Other countries, including Indonesia are putting a stop to raw exports and requiring domestic processing and beneficiation of mining output.

Last year according to an Ernst & Young survey of the world’s 30 largest miners, resource nationalism jumped to the top of the risk list in 2011 from fourth in 2010, after 25 countries announced their intentions to increase their take of the mining industry’s profits and others contemplate outright nationalization.

The Vancouver Sun reports smaller operators would be hurt much more than major projects and sums up the situation this way: “Cash-rich mining companies, raking in profits from metal prices that are well above historical levels, have emerged as easy targets for governments. Higher taxes and royalties on big miners are often used by politicians as populist moves to help rally the public and serve as platforms ahead of elections.”

MINING.com reported in January as attractive deposits become harder and harder to find in traditional markets, miners – especially those exploring for gold – are pushing the limits of the political risk they are willing to take on.

Research house Maplecroft in its 2012 political risk atlas identifies DR Congo, South Sudan, Myanmar, Turkmenistan, Iran, Guinea, Zimbabwe, Venezuela, Iraq, Bolivia, Russia, Kazakhstan, Angola, Nigeria and Libya as resource nationalism hotspots.

As an indication of how Indonesia’s move has surprised the industry it was missing from Maplecroft’s list released in January of countries that faced “extreme risk” and the researcher actually said investment risk in the country had decreased from the year before.

Also missing was Papua New Guinea which this year heads into elections that many observers have warned is bound to lead to civil unrest. In August last year the country’s leaders introduced a plan to hand state ownership of mineral and energy resources to landowners, a move that may prove disastrous to foreign miners developing massive projects and pushing into new regions of the resource-rich country.

Eurasia Group points out that already the world’s biggest gold mines are in so-called frontier markets:

- Uzbekistan (state-owned Muruntau)

- Papua New Guinea (Lihir, owned by Newcrest Mining and Harmony’s Wafi-Golpu project that has potential to rival Lihir in size)

- Mongolia (Ivanhoe and Rio Tinto’s Oyu Tolgoi, which last year became a state target)

And new mega-mine projects such as Newmont’s $4.8 billion Conga project in Peru, Barrick’s Pascua Lama (straddling Chile and Argentina) face opposition from environmentalists and locals.

Telah dibuka Depo baru PT. Central Bearindo International yang berlokasi di Cikarang.